The construction industry has long relied on scheduling methods to manage complex projects. While the Critical Path Method (CPM) remains dominant, a refined approach called Location-Based Management System (LBMS) is gaining traction by combining the strengths of CPM with the precision of location-based scheduling. This system isn’t merely a theoretical exercise; it builds upon decades of practical application, tracing its roots back to the Empire State Building and evolving through systematic development in Finland during the 1980s and 1990s.

The Evolution from Line-of-Balance to LBMS

Early location-based methods, like Line-of-Balance, aimed to optimize production across identical locations. However, CPM’s analytical power and ability to model change impacts led to its widespread adoption. LBMS bridges this gap by integrating location-based precision with a modified CPM algorithm. The core principle: forcing tasks to be continuous. This subtle adjustment delays the start of subsequent locations within a task, ensuring uninterrupted workflow.

Optimizing Flow: The Core of LBMS

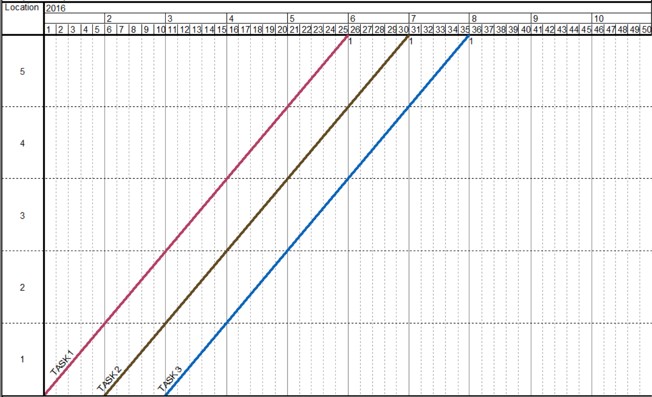

LBMS schedule optimization begins with a continuous flowline (Figure 1). The system then eliminates gaps by adjusting production rates, effectively removing float from the schedule. This isn’t about squeezing more work from crews; it’s about optimizing flow. Introducing buffers between tasks allows for variability without disrupting downstream operations. Case studies demonstrate that adopting LBMS can reduce project durations by up to 10% without increasing resource use.

Figure 1: A simple flowline schedule of three tasks. Task 2 is faster than others and its start date has been pulled to start later. Red circles indicate areas of opportunity for optimization. Scheduled total duration is 45 days.

Figure 2: The flowlines of Figure 1 have been aligned by slowing down task 2. The scheduled total duration is 35 days, achieved by decreasing resources.

Control Through Forecasting: Preventing Problems Before They Happen

Unlike CPM, which relies on monthly updates and assumes consistent production, LBMS utilizes real-time forecasting. Actual progress is visualized against the planned schedule, with deviations immediately apparent. When buffers are depleted and forecast lines clash (Figure 3), an alarm triggers, alerting management to potential issues. This proactive approach prevents cascading delays, which can otherwise inflate project durations by 10%.

Figure 3: Three day buffers have been added to the plan of Figure 2. Task 1 started on time but is going too slowly (dotted line). Forecast line (dashed line) is based on actual production rate. An alarm dot is shown where task 1 has used all its buffer and will cause a problem for task 2. The alarm is seven days away, giving management time to prevent the problem.

Complementary Systems: LBMS and the Last Planner System

LBMS excels at technical optimization, but it doesn’t replace human collaboration. The Last Planner System (LPS) focuses on social processes, constraint screening, and weekly commitment. Combining LPS with LBMS creates a powerful synergy. While LBMS forecasts highlight production risks, LPS ensures that constraints are addressed before they disrupt workflow. This integrated approach brings more issues to the surface earlier, allowing teams to solve problems proactively.

The Key Difference: Flow vs. Dates

LBMS and CPM share similarities, but their core philosophies diverge. CPM prioritizes hitting dates, while LBMS focuses on maximizing production speed and preventing disruptions. By forcing continuous flow, eliminating float, and utilizing real-time forecasting, LBMS delivers superior control and efficiency.

In conclusion, LBMS offers a refined approach to construction scheduling, blending technical precision with proactive control. Its ability to prevent problems before they happen makes it particularly well-suited for lean construction projects implementing the Last Planner System. By prioritizing flow, speed, and collaboration, LBMS unlocks significant efficiency gains and delivers superior project outcomes